Zifukwa zowotcherera za SMT

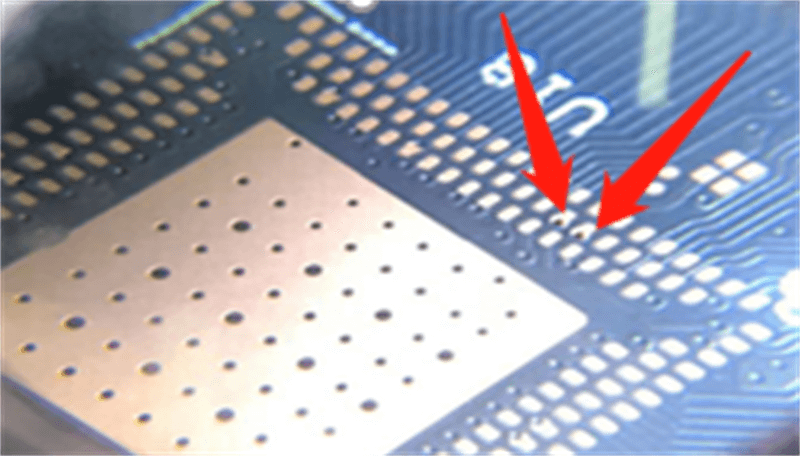

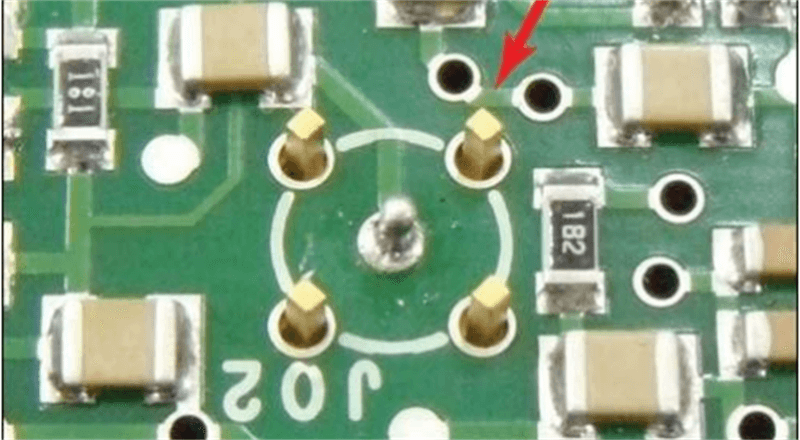

1. PCB pad kapangidwe zolakwika

Mu mapangidwe ndondomeko ya ena PCB, chifukwa danga ndi laling'ono, dzenje akhoza ankaimba pa pedi, koma solder phala ali fluidity, amene akhoza kudutsa mu dzenje, chifukwa palibe solder phala mu kuwotcherera reflow, kotero pamene pini ndi osakwanira kudya malata, zidzachititsa kuwotcherera pafupifupi.

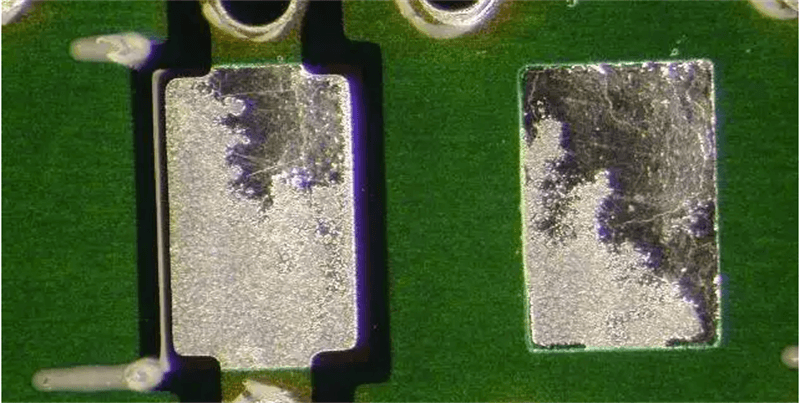

2.Pad pamwamba makutidwe ndi okosijeni

Mukakonzanso pad yokhala ndi okosijeni, kuwotchereranso kumabweretsa kuwotcherera, kotero kuti padyo ikawotchera, imayenera kuumitsa kaye. Ngati oxidation ndi yayikulu, iyenera kusiyidwa.

Kutentha kwa 3.Reflow kapena nthawi yotentha ya zone sikokwanira

Pambuyo pa chigamba kumalizidwa, kutentha sikokwanira pamene akudutsa reflow preheating zone ndi nthawi zonse kutentha zone, chifukwa ena otentha Sungunulani kukwera malata kuti sizinachitike pambuyo kulowa mkulu kutentha reflow zone, chifukwa chosakwanira malata kudya wa chigawo pini, chifukwa cha kuwotcherera pafupifupi.

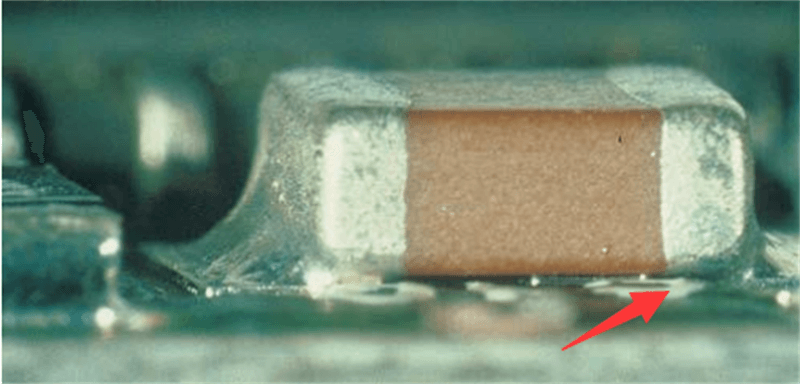

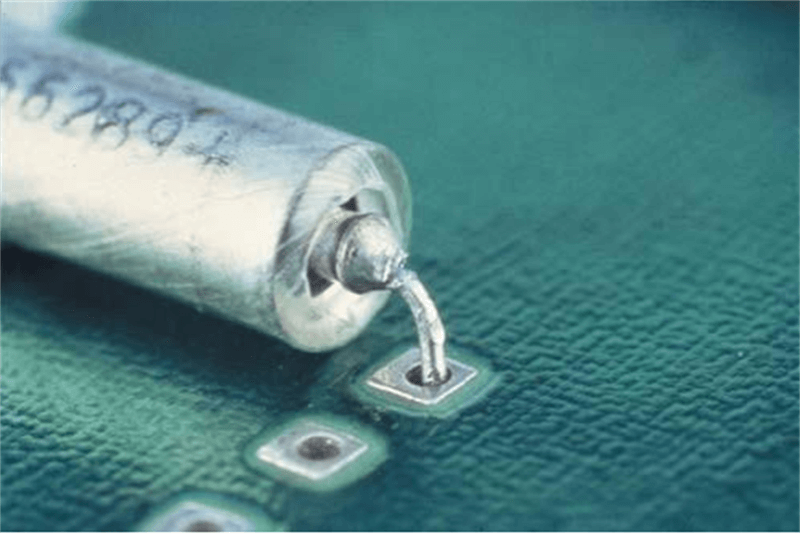

4.Solder phala kusindikiza ndi zochepa

Pamene solder phala ndi brushed, mwina chifukwa cha mipata ang'onoang'ono mu mauna zitsulo ndi kupanikizika kwambiri kwa scraper kusindikiza, kuchititsa zochepa solder phala kusindikiza ndi volatilization mofulumira wa solder phala kwa reflow kuwotcherera, chifukwa mu kuwotcherera pafupifupi.

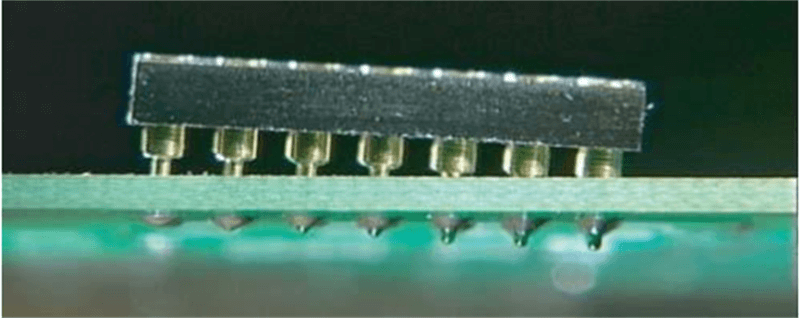

5.Zida zapamwamba kwambiri

Pamene chipangizo cha pini chapamwamba ndi SMT, zikhoza kukhala kuti pazifukwa zina, chigawocho ndi chopunduka, bolodi la PCB likupindika, kapena kupanikizika koipa kwa makina oyika sikokwanira, zomwe zimapangitsa kusungunuka kosiyanasiyana kwa solder, zomwe zimapangitsa kuti pakhale kuwotcherera.

Zifukwa zowotcherera za DIP

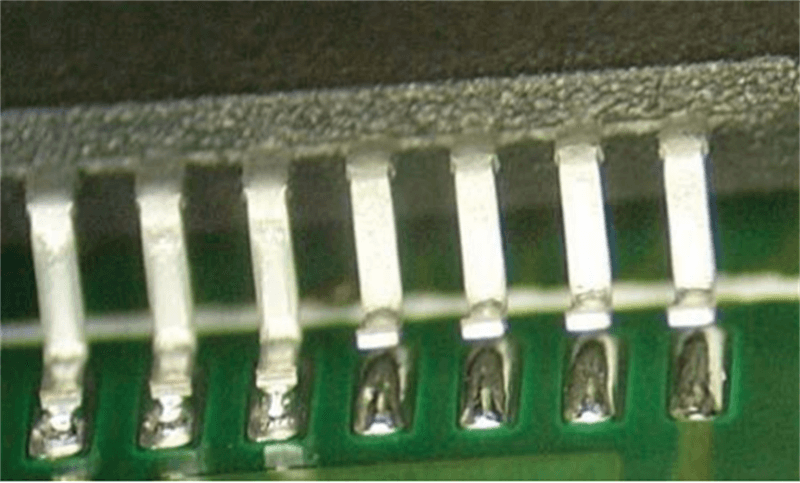

1.PCB pulagi-mu dzenje mapangidwe zolakwika

PCB pulagi-mu dzenje, kulolerana ndi pakati ± 0.075mm, PCB ma CD dzenje ndi lalikulu kuposa pini ya chipangizo thupi, chipangizo adzakhala lotayirira, kuchititsa malata osakwanira, kuwotcherera pafupifupi kapena kuwotcherera mpweya ndi mavuto ena khalidwe.

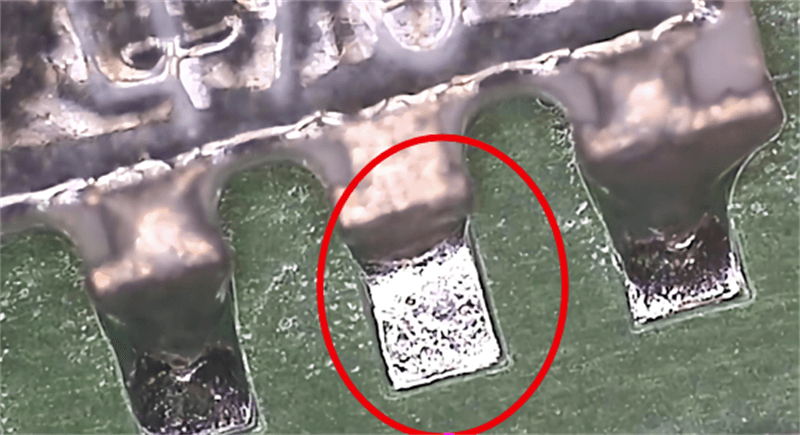

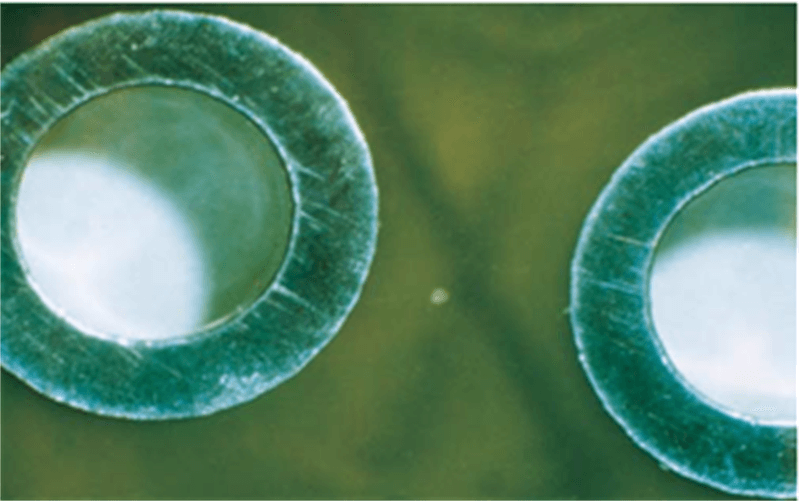

2.Pad ndi dzenje makutidwe ndi okosijeni

Mabowo a PCB ndi odetsedwa, okosijeni, kapena kuipitsidwa ndi zinthu zabedwa, mafuta, madontho a thukuta, ndi zina zambiri, zomwe zingapangitse kuti pakhale kuwotcherera bwino kapena kusakhala ndi weldability, zomwe zimapangitsa kuwotcherera pafupifupi ndi kuwotcherera mpweya.

3.PCB bolodi ndi chipangizo khalidwe zinthu

Nagula matabwa PCB, zigawo zikuluzikulu ndi solderability ena si oyenerera, palibe mayeso okhwima kuvomereza wachitika, ndipo pali mavuto khalidwe monga kuwotcherera pafupifupi pa msonkhano.

4.PCB bolodi ndi chipangizo inatha

Nagula PCB matabwa ndi zigawo zikuluzikulu, chifukwa kuwerengera nthawi yaitali kwambiri, anakhudzidwa ndi malo osungiramo katundu, monga kutentha, chinyezi kapena mpweya zikuwononga, chifukwa mu kuwotcherera zochitika monga kuwotcherera pafupifupi.

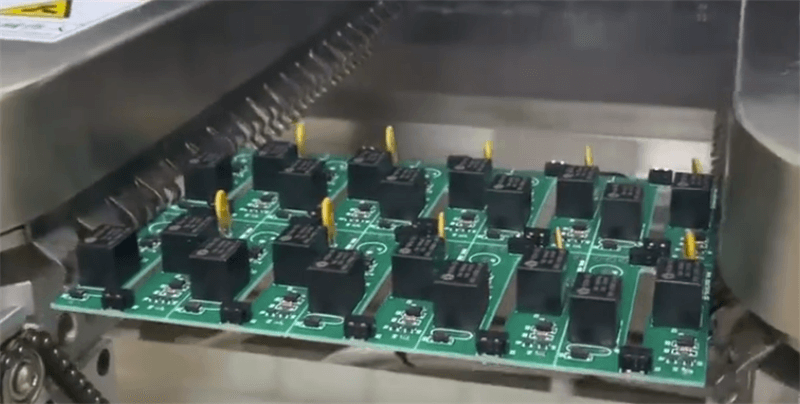

5.Wave soldering zida zinthu

The mkulu kutentha mu yoweyula kuwotcherera ng'anjo kumabweretsa inapita patsogolo makutidwe ndi okosijeni wa zinthu solder ndi pamwamba pa zinthu m'munsi, chifukwa mu kuchepetsedwa adhesion wa pamwamba pa madzi solder zakuthupi. Kuphatikiza apo, kutentha kwambiri kumawononganso zinthu zoyambira pansi, zomwe zimapangitsa kuchepa kwa capillary komanso kusalumikizana bwino, zomwe zimapangitsa kuwotcherera.

Nthawi yotumiza: Jul-11-2023