Tsatanetsatane wa njira yopangira PCBA (kuphatikiza njira yonse ya DIP), bwerani mudzawone!

"Wave Soldering Process"

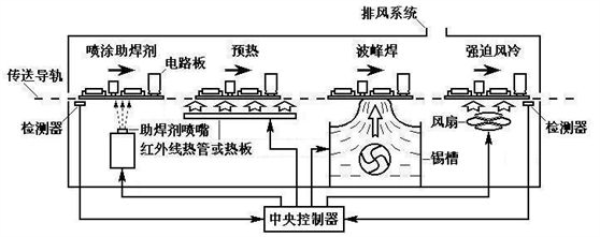

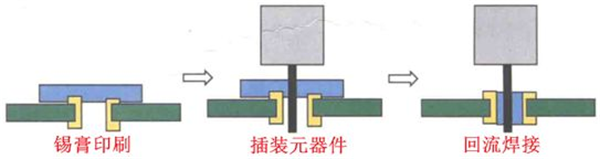

Wave soldering nthawi zambiri ndi njira yowotcherera pazida zamapulagi. Ndi njira yomwe solder yamadzimadzi yosungunuka, mothandizidwa ndi mpope, imapanga mawonekedwe enieni a solder wave pamtunda wamadzimadzi a thanki ya solder, ndipo PCB ya chigawo choyikidwacho imadutsa pamtunda wa solder wave pamtundu wina. ngodya ndi kumiza ena kuya pa unyolo kufala kukwaniritsa solder olowa kuwotcherera, monga momwe chithunzi pansipa.

Mayendedwe ake onse ali motere: kuyika kwa chipangizo --PCB loading -- wave soldering --PCB unloading --DIP pin trimming -- kuyeretsa, monga momwe tawonetsera pa chithunzi pansipa.

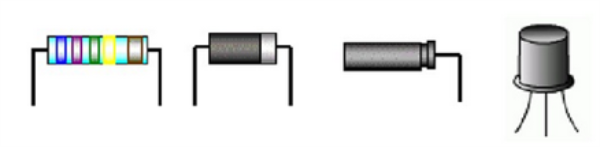

1.THC kuyika luso

1. Kupanga pini

Zipangizo za DIP ziyenera kuumbidwa musanaziike

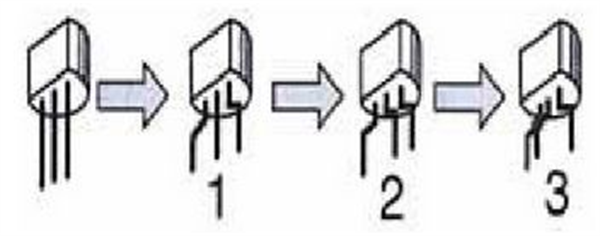

(1)Kupanga chigawo chopangidwa ndi manja: Pini yopindika imatha kupangidwa ndi ma tweezers kapena screwdriver yaying'ono, monga momwe chithunzi chili pansipa.

(2) Makina opangira zida zopangira zinthu: mawonekedwe a makina azinthu amamalizidwa ndi makina apadera opangira, mfundo yake yogwirira ntchito ndi yakuti wodyetsa amagwiritsa ntchito kugwedeza kudyetsa zinthu, (monga plug-in transistor) yokhala ndi chogawa kuti apeze. transistor, sitepe yoyamba ndikupinda zikhomo kumbali zonse za kumanzere ndi kumanja; Gawo lachiwiri ndikupinda pini yapakati kumbuyo kapena kutsogolo kuti ipangidwe. Monga momwe tawonetsera pa chithunzi chotsatira.

2. Ikani zigawo

Kupyolera mu teknoloji yolowetsa dzenje imagawidwa mu kuyika kwamanja ndi kuyika zida zamakina zokha

(1) Kuyika pamanja ndi kuwotcherera kumayenera kuyika kaye zigawo zomwe zimafunikira kukhazikika mwamakina, monga choyikapo chozizirira, bulaketi, kopanira, ndi zina, za chipangizo chamagetsi, kenako ndikuyika zida zomwe zimafunikira kuwotcherera ndi kukhazikika. Musakhudze zikhomo zamagulu ndi zojambulazo zamkuwa pa mbale yosindikizira mwachindunji pamene mukulowetsa.

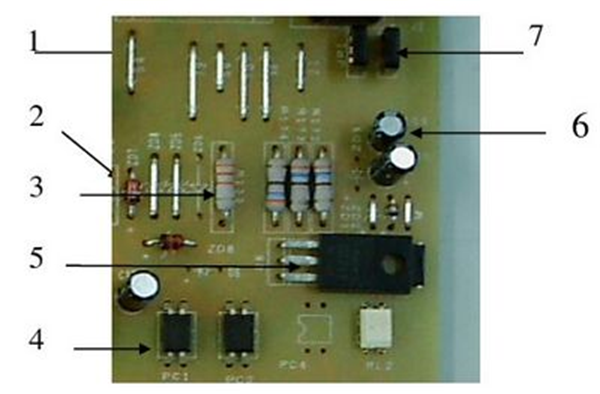

(2) Mechanical automatic plug-in (yotchedwa AI) ndiye ukadaulo wapamwamba kwambiri wopanga makina pakuyika zinthu zamakono zamagetsi. Kuyika kwa zida zamakina zodziwikiratu kuyenera choyamba kuyika zigawozo zokhala ndi kutalika kocheperako, kenako ndikuyika zigawozo zokhala ndi utali wokwera. Zigawo zazikuluzikulu zamtengo wapatali ziyenera kuikidwa poika komaliza. Kuyika kwa chivundikiro cha kutentha, bulaketi, kopanira, ndi zina zotere ziyenera kukhala pafupi ndi njira yowotcherera. Mndandanda wamagulu a PCB ukuwonetsedwa mu chithunzi chotsatirachi.

3. Wave soldering

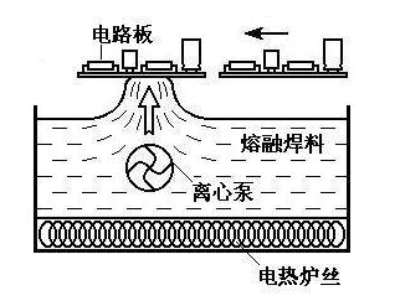

(1) Mfundo yogwirira ntchito ya ma wave soldering

Wave soldering ndi mtundu waukadaulo womwe umapanga mawonekedwe enaake a solder wave pamwamba pa solder wosungunuka wamadzimadzi pogwiritsa ntchito kupopera mphamvu, ndipo amapanga malo a solder mu malo opangira ma pini pomwe gawo la msonkhano lomwe limayikidwa ndi chigawocho likudutsa pa solder. gwedezani pa ngodya yokhazikika. chigawo choyamba preheated mu kuwotcherera makina preheating zone pa ndondomeko kufala ndi unyolo conveyor (gawo preheating ndi kutentha akwaniritsa akadali olamulidwa ndi anakonzeratu kutentha pamapindikira). Mu kuwotcherera kwenikweni, nthawi zambiri ndikofunikira kuwongolera kutentha kwa preheating ya gawo lapansi, kotero zida zambiri zidawonjezera zida zowunikira kutentha (monga ma infrared detectors). Pambuyo potenthetsera, msonkhanowo umapita munjira yowotcherera. Tanki ya malata imakhala ndi solder yamadzi osungunuka, ndipo mphuno yomwe ili pansi pa thanki yachitsulo imapopera nsonga yokhazikika ya solder yosungunuka, kotero kuti pamene kuwotcherera kwa chigawocho kumadutsa pamafunde, kumatenthedwa ndi solder wave. , ndi solder yoweyula imanyowetsanso malo owotcherera ndikukulitsa kudzaza, pomaliza kukwaniritsa njira yowotcherera. Mfundo yake yogwirira ntchito ikuwonetsedwa mu chithunzi pansipa.

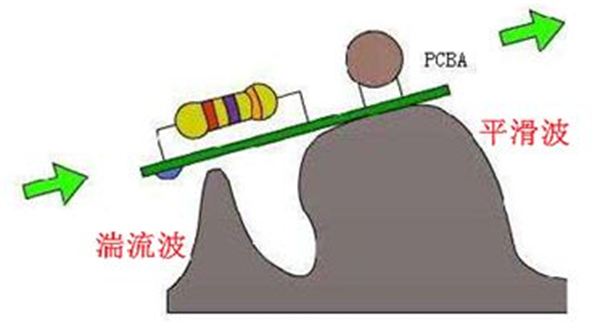

Wave soldering amagwiritsa ntchito mfundo yosinthira kutentha kwa convection kutenthetsa malo owotcherera. Wosungunula solder yoweyula amachita ngati gwero kutentha, pa dzanja limodzi akuyenda kutsuka pini kuwotcherera m'dera, Komano amakhalanso ndi kutentha conduction udindo, ndi pini kuwotcherera m'dera ndi mkangano pansi pa izi. Pofuna kuonetsetsa kuti malo otsekemera amawotchera, mafunde a solder nthawi zambiri amakhala ndi m'lifupi mwake, kotero kuti pamene kuwotcherera pamwamba pa chigawocho kumadutsa mumtsinje, pali kutentha kokwanira, kunyowa, ndi zina zotero. Pachikhalidwe cha ma wave soldering, mafunde amodzi amagwiritsidwa ntchito, ndipo mafunde amakhala athyathyathya. Pogwiritsa ntchito solder yotsogolera, panopa imatengedwa ngati mawonekedwe awiri wave. Monga momwe tawonetsera pa chithunzi chotsatira.

Pini ya chigawocho amapereka njira kwa solder kuviika mu metallized kudzera dzenje mu boma olimba. Piniyo ikakhudza mafunde a solder, solder yamadzimadzi imakwera papini ndi khoma la dzenje pogwiritsa ntchito mphamvu ya pamwamba. The capillary zochita za metallized kudzera mabowo bwino solder kukwera. Pambuyo solder ifika pa PcB pad, imafalikira pansi pa zochitika zapang'onopang'ono pamwamba pa pedi. Solder yokwera imakhetsa mpweya wotuluka ndi mpweya kuchokera pabowo, motero amadzaza dzenje ndikupanga cholumikizira cha solder pambuyo pozizira.

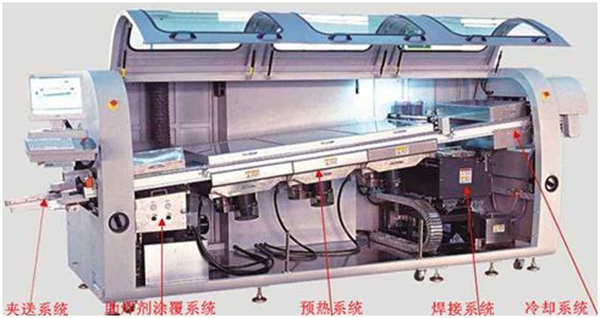

(2) Zigawo zazikulu za makina owotcherera yoweyula

Makina owotcherera amapangidwa makamaka ndi lamba wolumikizira, chotenthetsera, thanki ya malata, pampu, ndi chipangizo chotulutsa thovu (kapena kupopera). Iwo makamaka anawagawa flux kuwonjezera zone, preheating zone, kuwotcherera zone ndi kuzirala zone, monga momwe chithunzi chotsatirachi.

3. Kusiyana kwakukulu pakati pa kuwotcherera kwa mafunde ndi kuwotchereranso

Kusiyanitsa kwakukulu pakati pa kuwotcherera kwa mafunde ndi kuwotchereranso ndikuti gwero la kutentha ndi njira yoperekera solder pakuwotcherera ndizosiyana. Mu soldering yoweyula, solder imatenthedwa kale ndikusungunuka mu thanki, ndipo mafunde a solder opangidwa ndi pampu amatenga mbali ziwiri za gwero la kutentha ndi kupereka solder. Mafunde osungunuka amatenthetsa mabowo, mapepala, ndi zikhomo za PCB, komanso amapereka solder wofunikira kuti apange ma solder joints. Mu reflow soldering, solder (solder phala) imaperekedwa kale kumalo otsekemera a PCB, ndipo udindo wa gwero la kutentha panthawi yowonjezereka ndikusungunulanso solder.

(1) 3 Chiyambi cha njira yosankha yowongolerera

Wave soldering zida anatulukira kwa zaka zoposa 50, ndipo ali ndi ubwino mkulu kupanga dzuwa ndi linanena bungwe lalikulu popanga zigawo zikuluzikulu dzenje ndi matabwa dera, kotero izo poyamba anali zida zofunika kwambiri kuwotcherera pakupanga misa basi. zinthu zamagetsi. Komabe, pali zoletsa zina pakugwiritsa ntchito kwake: (1) magawo azowotcherera ndi osiyana.

Zolumikizira zosiyanasiyana za solder pa bolodi loyang'anira dera lomwelo zingafunike magawo osiyanasiyana azowotcherera chifukwa cha mawonekedwe awo osiyanasiyana (monga mphamvu ya kutentha, katayanidwe ka pini, zofunikira pakulowa kwa malata, ndi zina). Komabe, khalidwe la yoweyula soldering ndi kumaliza kuwotcherera zimfundo zonse solder pa bolodi lonse dera pansi pa magawo ofanana anapereka, kotero osiyana olowa solder ayenera "kukhazikitsa" wina ndi mzake, zomwe zimapangitsa yoweyula soldering kukhala kovuta kwambiri kukwaniritsa kuwotcherera. zofunikira za matabwa apamwamba kwambiri;

(2) Ndalama zoyendetsera ntchito.

Pogwiritsira ntchito zida zachikhalidwe zowotchera, kupopera mbewu mankhwalawa kwa flux ndi kupanga malata kumabweretsa ndalama zambiri zogwirira ntchito. Makamaka pamene kuwotcherera opanda kutsogolera, chifukwa mtengo wa solder wopanda kutsogolera ndi woposa nthawi 3 wa solder wotsogolera, kuwonjezeka kwa ndalama zogwiritsira ntchito chifukwa cha malata ndi zodabwitsa kwambiri. Kuonjezera apo, solder yopanda kutsogolera ikupitiriza kusungunula mkuwa pa pad, ndipo mapangidwe a solder mu silinda ya malata adzasintha pakapita nthawi, zomwe zimafuna nthawi zonse kuwonjezera malata oyera ndi siliva wodula kuti athetse;

(3) Kukonza ndi kukonza zovuta.

Kuthamanga kotsalira pakupanga kudzakhalabe mu njira yopatsirana ya soldering yoweyula, ndipo malata opangidwa ndi malata amafunika kuchotsedwa nthawi zonse, zomwe zimabweretsa zovuta kwambiri kukonza ndi kukonza zipangizo kwa wogwiritsa ntchito; Pazifukwa izi, kusankha wave soldering kudayamba.

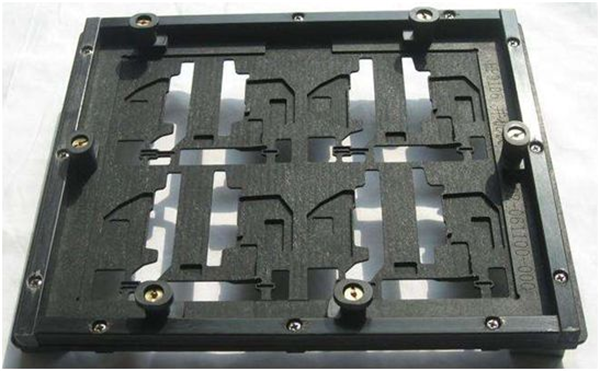

Otchedwa PCBA kusankha yoweyula soldering akadali akugwiritsa ntchito ng'anjo ya malata yapachiyambi, koma kusiyana kwake ndikuti bolodi iyenera kuikidwa mu chonyamulira cha malata, zomwe timanena nthawi zambiri za ng'anjo ya ng'anjo, monga momwe chithunzichi chili pansipa.

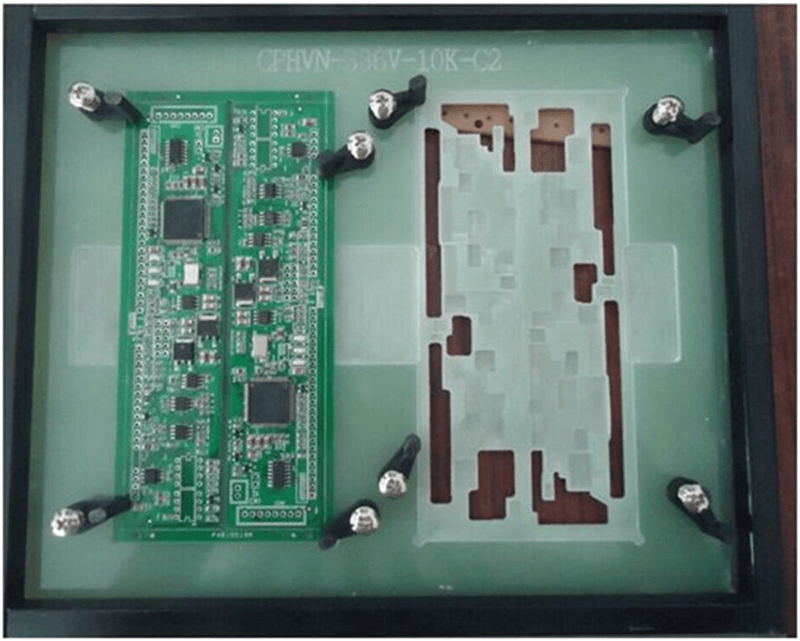

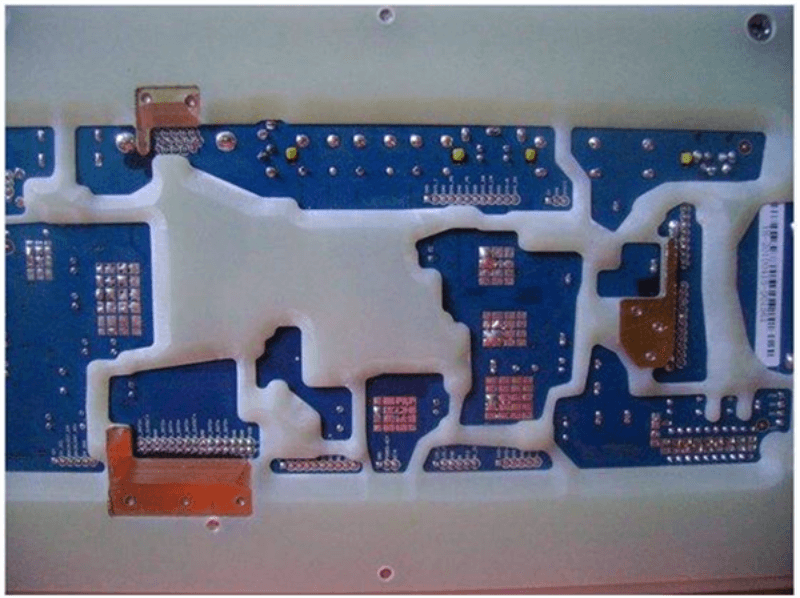

Ziwalo zomwe zimafunikira kuti ziwonjezeke zimayikidwa pa malata, ndipo zina zimatetezedwa ndi zotchingira galimoto, monga momwe zilili pansipa. Izi zili ngati kuvala buoy mu dziwe losambira, malo ophimbidwa ndi moyo sangapeze madzi, ndipo m'malo mwake ndi mbaula ya malata, malo ophimbidwa ndi galimoto sangatenge malata, ndipo padzakhala palibe vuto lakusungunulanso malata kapena magawo akugwa.

"Kupyolera mu hole reflow Welding Process"

Kuwotcherera kudzera m'mabowo ndi njira yowotcherera yopangiranso zida zoyikapo, zomwe zimagwiritsidwa ntchito makamaka popanga mbale zolumikizirana zomwe zili ndi mapulagi ochepa. Pakatikati paukadaulo ndi njira yogwiritsira ntchito solder phala.

1. Chiyambi cha ndondomeko

Malinga ndi ntchito njira solder phala, kudzera dzenje reflow kuwotcherera akhoza kugawidwa mu mitundu itatu: chitoliro kusindikiza kudzera dzenje reflow kuwotcherera ndondomeko, solder phala kusindikiza kudzera dzenje reflow kuwotcherera ndondomeko ndi kuumbidwa malata pepala kudzera dzenje reflow kuwotcherera ndondomeko.

1) Tubular kusindikiza kudzera dzenje reflow kuwotcherera ndondomeko

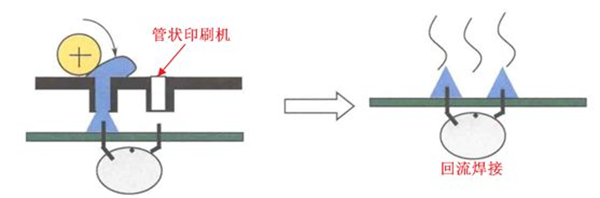

Kusindikiza kwa tubular kudzera pa hole reflow kuwotcherera ndiye njira yoyambilira yogwiritsira ntchito njira zowotcherera zomwe zimagwiritsidwa ntchito kwambiri popanga chochunira cha TV. Pakatikati pa ndondomekoyi ndi solder phala tubular press, ndondomekoyi ikuwonetsedwa mu chithunzi pansipa.

2) Solder phala kusindikiza kudzera dzenje reflow kuwotcherera ndondomeko

Solder phala kusindikiza kudzera dzenje reflow kuwotcherera ndondomeko panopa ndi ambiri ntchito kudzera dzenje reflow kuwotcherera ndondomeko, makamaka ntchito PCBA wosanganiza munali ochepa mapulagi-ins, ndondomeko n'zogwirizana kwathunthu ndi ochiritsira reflow kuwotcherera ndondomeko, palibe zida ndondomeko wapadera ndi chofunika, chofunika chokha ndicho welded pulagi-mu zigawo zikuluzikulu ayenera kukhala oyenera kudzera dzenje reflow kuwotcherera, ndondomeko zikusonyezedwa mu chithunzi zotsatirazi.

3) Kuumba lata pepala kudzera dzenje reflow kuwotcherera

Kuumbidwa tini pepala kudzera dzenje reflow kuwotcherera ndondomeko zimagwiritsa ntchito zolumikizira Mipikisano pini, solder si solder phala koma kuumbidwa pepala malata, zambiri ndi cholumikizira Mlengi mwachindunji anawonjezera, msonkhano akhoza kutenthedwa.

Kupyolera mu dzenje reflow mapangidwe zofunika

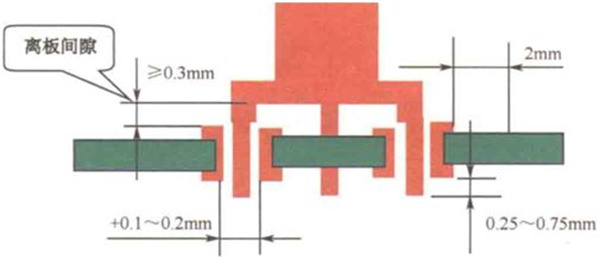

1.PCB kapangidwe zofunika

(1) Oyenera PCB makulidwe zosakwana kapena wofanana 1.6mm bolodi.

(2) Kutalika kochepa kwa pad ndi 0.25mm, ndipo phala losungunuka la solder "lokoka" kamodzi, ndipo mkanda wa malata sunapangidwe.

(3) Chigawo chopanda bolodi (Kuyimirira) chiyenera kukhala chachikulu kuposa 0.3mm

(4) Kutalika koyenera kwa chiwongolero chotuluka pabedi ndi 0.25 ~ 0.75mm.

(5) Mtunda wocheperako pakati pa magawo abwino otalikirana monga 0603 ndi pad ndi 2mm.

(6) Kutsegula kwakukulu kwa mauna achitsulo kumatha kukulitsidwa ndi 1.5mm.

(7) Pobowo ndi m'mimba mwake wotsogolera kuphatikiza 0.1 ~ 0.2mm. Monga momwe tawonetsera pa chithunzi chotsatirachi.

"Zofunikira pakutsegula zenera lachitsulo"

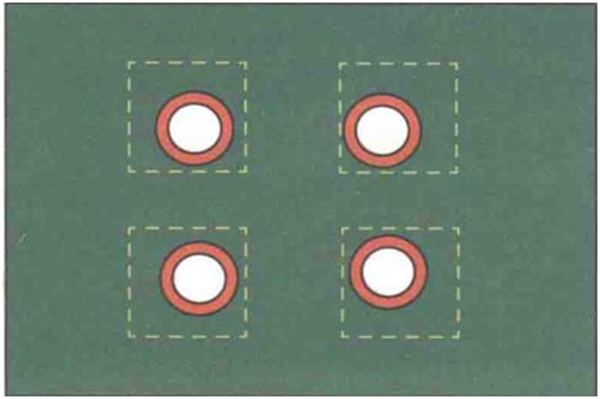

Kawirikawiri, kuti mukwaniritse 50% kudzaza dzenje, zenera lachitsulo lazitsulo liyenera kukulitsidwa, kuchuluka kwapadera kwa kunja kumayenera kutsimikiziridwa malinga ndi makulidwe a PCB, makulidwe a zitsulo zachitsulo, kusiyana pakati pa dzenje ndi kutsogolera. ndi zinthu zina.

Nthawi zambiri, malinga ngati kukula sikudutsa 2mm, phala la solder lidzakokedwa ndikudzazidwa mu dzenje. Kuyenera kudziŵika kuti kukulitsa kunja sangathe wothinikizidwa ndi chigawo phukusi, kapena kupewa phukusi thupi la chigawo chimodzi, ndi kupanga malata mkanda mbali imodzi, monga momwe chithunzi chotsatirachi.

"Chiyambi cha ochiritsira Assembly Process ya PCBA"

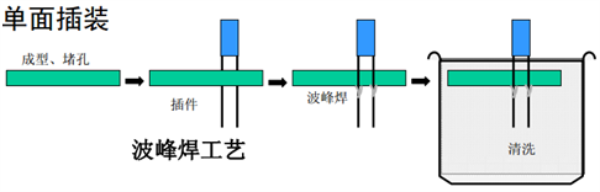

1) Kuyika mbali imodzi

Njira yoyendetsera ntchitoyi ikuwonetsedwa mu chithunzi pansipa

2) Kuyika mbali imodzi

Njira yoyendetsera ntchitoyi ikuwonetsedwa mu Chithunzi 5 pansipa

Kupanga zikhomo za chipangizo mu soldering yoweyula ndi imodzi mwazinthu zosagwira ntchito kwambiri pakupanga, zomwe zimabweretsa chiwopsezo cha kuwonongeka kwa electrostatic ndikutalikitsa nthawi yobereka, komanso kumawonjezera mwayi wolakwa.

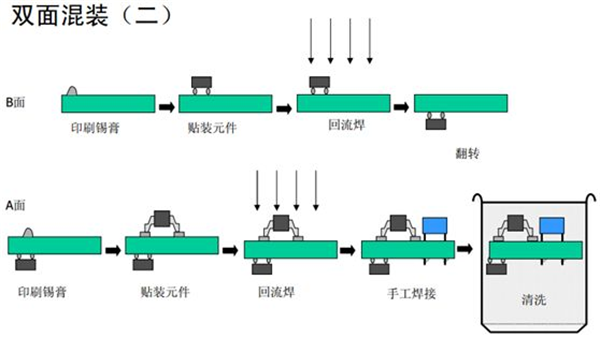

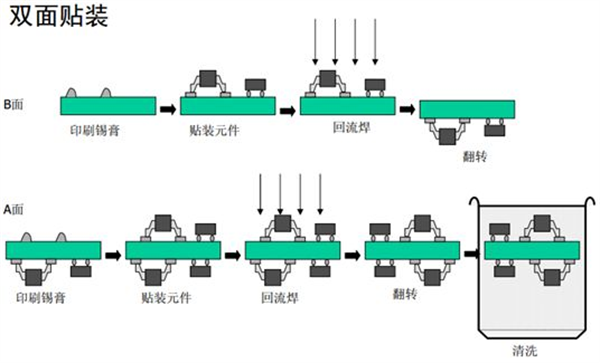

3) Kuyika mbali ziwiri

Njira yoyendetsera ntchitoyi ikuwonetsedwa mu chithunzi pansipa

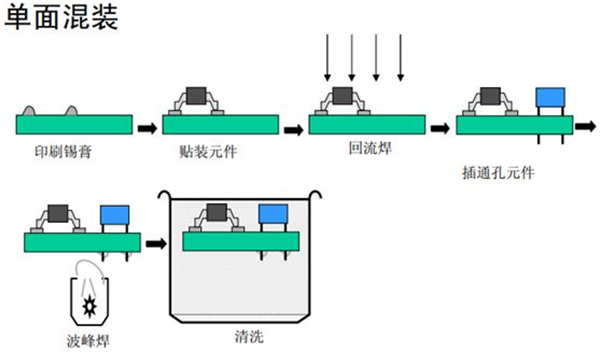

4) Mbali imodzi yosakanikirana

Njira yoyendetsera ntchitoyi ikuwonetsedwa mu chithunzi pansipa

Ngati pali zigawo zochepa zobowola, kuwotchereranso ndi kuwotcherera pamanja kungagwiritsidwe ntchito.

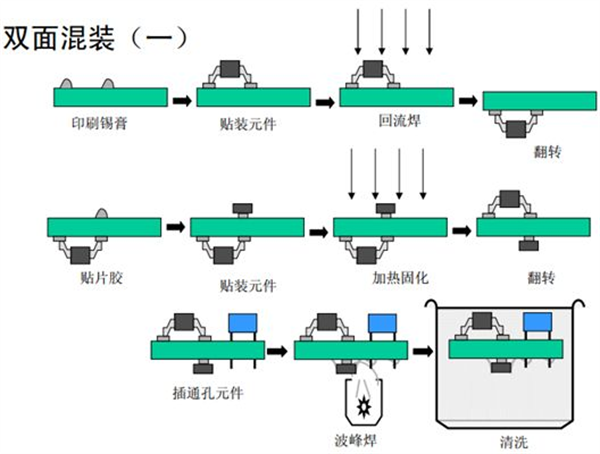

5) Kusakaniza kwa mbali ziwiri

Njira yoyendetsera ntchitoyi ikuwonetsedwa mu chithunzi pansipa

Ngati pali zida za SMD zokhala ndi mbali ziwiri ndi zigawo zochepa za THT, zida za plug-in zitha kukhala zotulukanso kapena kuwotcherera pamanja. Ndondomeko yoyendetsera ndondomeko ikuwonetsedwa pansipa.