PCB multilayer compaction ndi njira yotsatizana. Izi zikutanthauza kuti m'munsi mwa layering adzakhala chidutswa cha mkuwa zojambulazo ndi wosanjikiza prepreg anaika pamwamba. Chiwerengero cha zigawo za prepreg zimasiyanasiyana malinga ndi ntchito zofunika. Kuphatikiza apo, chigawo chamkati chimayikidwa pa prepreg billet wosanjikiza kenako ndikudzazidwa ndi prepreg billet wosanjikiza wokutidwa ndi zojambula zamkuwa. Laminate ya PCB yamitundu yambiri imapangidwa motero. Ikani laminates ofanana pamwamba pa mzake. Pambuyo powonjezeredwa chojambula chomaliza, mulu womaliza umapangidwa, wotchedwa "buku," ndipo mulu uliwonse umatchedwa "mutu."

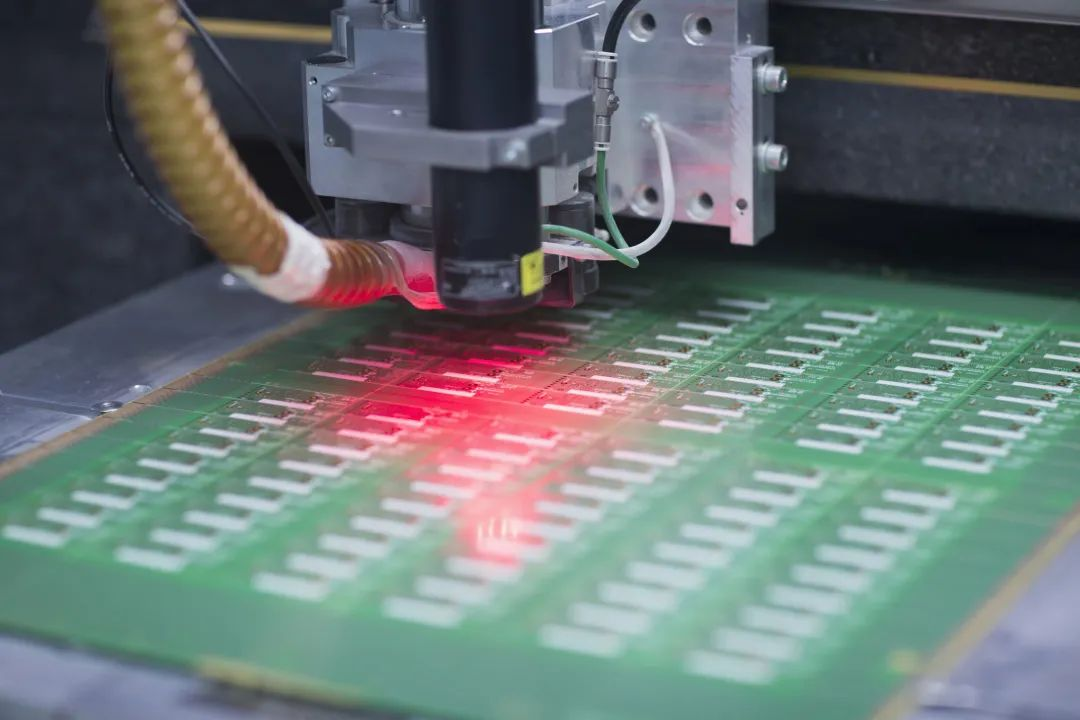

Bukuli likamaliza, limasamutsidwa ku makina osindikizira a hydraulic. Makina osindikizira a hydraulic amatenthedwa ndipo amagwiritsa ntchito mphamvu zambiri ndikupukuta bukhuli. Njirayi imatchedwa kuchiritsa chifukwa imalepheretsa kulumikizana pakati pa laminates ndi mzake ndipo imalola kuti utomoni wa prepreg ugwirizane ndi pachimake ndi zojambulazo. Zigawozi zimachotsedwa ndikuzizidwa kutentha kuti zilole kuti utomoni ukhazikike, motero amamaliza kupanga copper multilayer PCB kupanga.

Pambuyo podula mapepala osiyana siyana molingana ndi kukula kwake, mapepala osiyanasiyana amasankhidwa molingana ndi makulidwe a pepala kuti apange slab, ndipo slab laminated imasonkhanitsidwa mu unit yokakamiza malinga ndi ndondomeko ya ndondomeko. Kanikizani makina osindikizira mu makina opangira laminate kuti akanikizire ndi kupanga.

5 magawo a kutentha kutentha

(a) Preheating siteji: kutentha kumachokera ku firiji mpaka kutentha koyambirira kwa kuchiritsa kwamadzi, pomwe utomoni wapakati umatenthedwa, gawo lina la volatile limatulutsidwa, ndipo kupanikizika ndi 1/3 mpaka 1/2 ya kukakamiza kwathunthu.

(b) kutchinjiriza siteji: pamwamba wosanjikiza utomoni anachiritsidwa pa mlingo wotsika anachita. Pakatikati utomoni wosanjikiza ndi uniformly kutenthedwa ndi kusungunuka, ndipo mawonekedwe a utomoni wosanjikiza akuyamba kusakanikirana wina ndi mzake.

(c) Kutentha siteji: kuyambira kutentha kwa machiritso mpaka kutentha kwakukulu komwe kumatchulidwa panthawi ya kukanikiza, kuthamanga kwa kutentha sikuyenera kukhala kofulumira kwambiri, mwinamwake kuthamanga kwapamwamba kwapamwamba kudzakhala kofulumira kwambiri, ndipo sikungathe kuphatikizidwa bwino ndi utomoni wapakati, zomwe zimapangitsa kuti stratification kapena kupasuka kwa mankhwala omalizidwa.

(d) nthawi zonse kutentha siteji: pamene kutentha kufika pamtengo wapatali kwambiri kukhalabe siteji zonse, udindo wa siteji iyi ndi kuonetsetsa kuti pamwamba wosanjikiza utomoni bwinobwino anachiritsa, pachimake wosanjikiza utomoni ndi uniformly plasticized, ndi kuonetsetsa kusungunuka kuphatikiza pakati pa zigawo za mapepala zakuthupi, pansi pa zochita za kukakamizidwa kuti likhale yunifolomu wandiweyani lonse, ndiyeno yomalizidwa ntchito mankhwala kukwaniritsa mtengo kwambiri.

(e) Chigawo chozizirira: Pamene utomoni wapakati pa slab wachiritsidwa bwino ndikuphatikizidwa bwino ndi utomoni wapakati, ukhoza kukhazikika ndi kukhazikika, ndipo njira yoziziritsira ndikudutsa madzi ozizira mu mbale yotentha ya makina osindikizira, yomwe imatha kukhazikika mwachibadwa. Gawoli liyenera kuchitidwa pansi pa kukonzedwa kwa kukakamizidwa komweko, ndipo kuzizira koyenera kumayenera kuyendetsedwa. Pamene kutentha kwa mbale kumatsika pansi pa kutentha koyenera, kumasulidwa kwamphamvu kungathe kuchitika.

Nthawi yotumiza: Mar-07-2024